SikaGrout 215 Pumpable Shrinkage Compensated Cementitious Grout 25KG

SikaGrout 215 Pumpable Shrinkage Compensated Cementitious Grout 25KG

- Brand Sika

- Model: SK-G215-25

Description

SikaGrout 215 is a pumpable dual-shrinkage compensated, self-leveling, prebagged cementitious grout with extended working time to suit local ambient temperatures.

Characteristics / Advantages

▪ Easy to mix and apply.

▪ Good flow characteristics.

▪ Rapid strength development.

▪ High ultimate strengths.

▪ Impact resistant.

▪ Non-corrosive.

▪ Non-toxic.

▪ Chloride free.

▪ Dense and non-shrink (2-step expansion - Gaseous expansion in plastic stage & Crystalline expansion in hardened stage).

▪ Extended working time.

▪ Good pumping properties.

▪ Tested for compatibility with drinking water, PSB report 57S030976-SLE-2.

Specification

Product Information

▪ Packaging: 25 kg bag

▪ Appearance / Colour: Grey powder

▪ Shelf Life: 6 months from the date of production

▪ Storage Conditions: Store properly in original, unopened and undamaged sealed packaging in dry conditions at temperatures between +5 °C and +35 °C. ▪ Protect from direct sunlight, rain and water.

▪ Density: ~2.2 kg/l (depending on consistency and temperature)

▪ Maximum Grain Size: 1.2 mm

Technical Information

▪ Compressive Strength:

Flowable

- 1 day >25 N/mm²

- 7 days >45 N/mm²

- 28 days >60 N/mm²

- (ASTM C 109)

Pourable

- 1 day >30 N/mm²

- 7 days >50 N/mm²

- 28 days >65 N/mm²

- (ASTM C 109)

▪ Tensile Strength in Flexure:

Flowable

- 7 days ~7.0 N/mm²

- 28 days ~7.5 N/mm²

- (EN 196-1)

Pourable

- 7 days ~7.5 N/mm²

- 28 days ~8.0 N/mm²

- (EN 196-1)

▪ Expansion: 0.5–1.5 % (ASTM C 940) at 24 hours

Application Information

▪ Mixing Ratio:

Consistency: Water (L) per 25 kg of grout

- Flowable; 4.0–4.4

- Pourable: 3.6–4.0

- Stiff: 3.0–3.4 (for special applications such as anchoring of starter bars)

▪ Yield:

Flowable consistency

1.84 kg

- Water: 0.31 L

- Volume mortar: 1 L

25 kg

- Water: 4.2 L

- Volume mortar: 13.6 L

74 x 25 kg bags

- Water: 309 L

- Volume mortar: 1 m³

Pourable consistency

1.90 kg

- Water: 0.3 L

- Volume mortar: 1 L

25 kg

- Water: 4 L

- Volume mortar: 13.2 L

76 x 25 kg bags

- Water: 303 L

- Volume mortar: 1 m³

▪ Layer Thickness: 5 mm min. / 50 mm max. per pour

▪ Flowability:

Flowable

- Flow cone ~280 mm

- (ASTM C 230 modified)

Pourable

- Flow cone ~250 mm

- (ASTM C 230 modified)

▪ Ambient Air Temperature: +10 °C min. / +40 °C max.

▪ Substrate Temperature: +10 °C min. / +40 °C max.

Uses

SikaGrout®-215 is suitable for repairs to the following concrete structures:

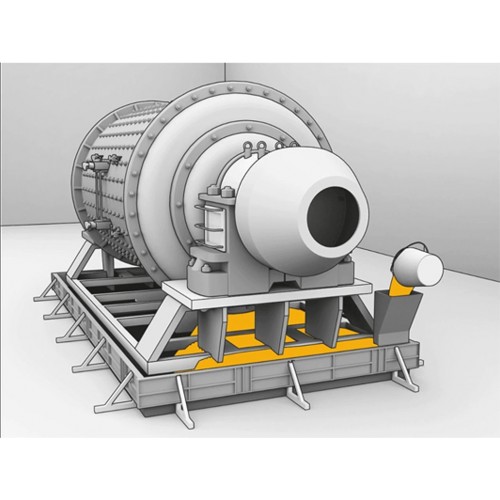

▪ Machine foundations

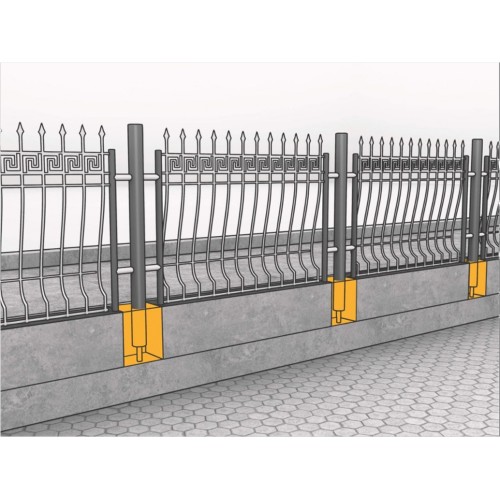

▪ Columns in precast construction

▪ Concrete anchors

▪ Bridge bearings

▪ Cavities

▪ Gaps

▪ Recesses

▪ Rail beds

▪ Honeycombs (pre-packed grouting)

SikaGrout®-215 is suitable for grouting works with clearances as low as 5 mm.

Application

• Use SikaGrout®-215 for grouting only.

• After mixing, stir lightly with a spatula for a few seconds to release any entrapped air. The grout is then poured immediately into the prepared formwork.

• When carrying out baseplate grouting, ensure sufficient pressure head is maintained for uninterrupted mortar flow.

• For formwork repair, the prepared formwork must be firmly in place and kept watertight.

• When placing grout over a large area, it is important to maintain a continuous flow throughout.

• Work sequence must be properly organised to ensure an uninterrupted flow.

• In large areas, SikaGrout®-215 may be pumped using heavy duty diaphragm pumps.

• Screw feed and piston pumps may also be used.

Specific Areas of Application

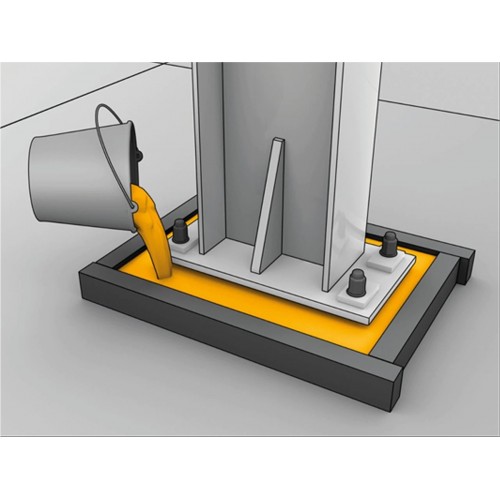

• Grouting under baseplate - pourable consistency

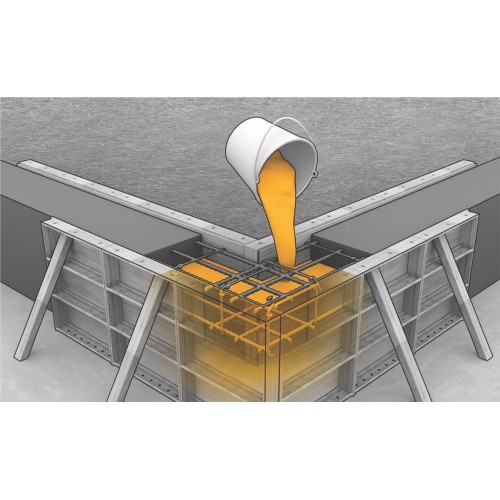

• Formwork grouting (example deep honeycombs, column reinforcements, etc.

- pouring method - flowable / pourable consistency

- prepacked method - flowable consistency.

• Grouting anchor bolts - stiff consistency

• Grouting large volumes - for sections thicker than 50 mm, it is necessary to fill SikaGrout®-215 with graded 10 mm silt free aggregates to minimise temperature rise generated during the curing stage. The quantity of aggregates should not exceed 1 part aggregates to 1 part SikaGrout®-215 by weight. For such mixes, a conventional concrete mixer and pump may be used.

To further ensure that air entrapped during mixing is allowed to fully escape, it may be necessary to make breather holes. Use steel rods or chains to assist the flow of the grout where necessary.

Important Considerations

▪ At temperatures below +20°C, setting time and strength development will be slower.

▪ Non-shrink grout contains additives which expand either during the plastic stage and / or the hardening stage to compensate for the shrinkage of the cementitious matrix. However, this ‘non-shrink’ property will be effective only if the material is not subjected to water loss.

▪ This is confirmed by a note in the ASTM C 1107

Standard Specification for packaged dry, hydraulic cement grout (non-shrinkable), which clarifies the behaviour of the non-shrink grout when subjected to some drying:

“Note 1: Since all conditions of use cannot be anticipated, this specification requires non-shrink grout to exhibit no shrinkage when tested in a laboratory controlled moist-cured environment, and requires only the reporting of the observed height change, usually shrinkage, when test specimens are subject to some degree of drying.”

Disclaimer

All product images shown are for illustration purposes only. Actual products may varies in term of size, type, brand, version, colour, and other relevant characteristics.