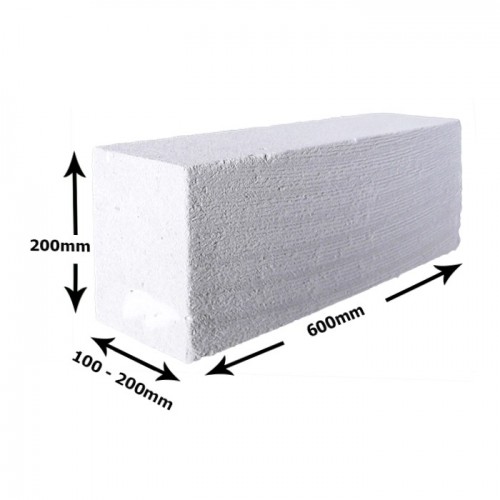

Starken DuraPro5™ Autoclaved Aerated Light-Weight Concrete (AAC) Block 125MM (T) x 600MM (L) x 200MM (H) S5

Starken DuraPro5™ Autoclaved Aerated Light-Weight Concrete (AAC) Block 125MM (T) x 600MM (L) x 200MM (H) S5

- Brand Starken

- Model: STK-DP5-125

Description

Starken Standard Blocks offer a fast, convenient and versatile solution for most walling requirements. Each block is equivalent to 7 pieces of common brick. Starken AAC blocks are easy to work with and can be cut to size with a tungsten carbide-tipped handsaw. This allows maximum flexibility and minimises wastage.

Application

- General internal & external walls.

- Party, compartment & separating walls.

- Acoustic & fire-rated walls.

- Only Block thickness 125mm & above are suitable for use as load-bearing walls.

Specification

| Property | Value |

| Length (L) x Height (H) | 600mm (L) x 200mm (H) |

| Thickness (T) | 100 - 200mm |

| Nominal Dry Density | 600 ± 50 kg/m³ |

| Working Density | 840 ± 50 kg/m³ |

| Compressive Strength | 5.5 MPa |

| Thermal Concuctivity, K | 0.244 W/m.k |

| Modulus of Elasticity | 1500 - 2500 MPa |

| Ultimate Tensile Strength | 0.44 - 0.55 MPa |

| Modulus of Rupture | 0.44 - 0.55 MPa |

| Standard Nominal Length & Height (MM) | Standard Nominal Thickness (MM) | M² per Pallet | No. of Pieces per Pallet |

| 600 x 200 | 100 | 21.60 | 180 |

| 125 | 17.30 | 144 | |

| 150 | 14.40 | 120 | |

| 200 | 10.10 | 84 |

AAC Benefits

| 1. Lightweight Starken AAC density is about one-fifth of that of normal concrete blocks, making it easily handled. Foundation (piles & pile caps) |

| 2. Fire Resistant More superior than traditional masonry for products with fire resistant up to 4 hours for a nominal block thickness of 100mm. Heat insulation more than 3 times superior to brick wall. |

| 3. Impact Resistant Wall erected using 100mm thick AAC products is classified as “Severe Duty” grade and able to withstand impact loads potentially resulting from rough usage. |

| 4. Cost Effective Speed and ease of installation result in cost savings compared to traditional masonry construction. |

| 5. Durable History of usage dated more than 50 years protecting building envelopes and remain durable even under extreme weather conditions. |

| 6. Eco-friendly Starken AAC to help reduce at least 30% of environmental waste, decrease 50% of greenhouse radiation and over 60% integrated energy on the surface of brick. |

| 7. Thermal Comfort & Energy Saving Starken AAC’s excellent thermal insulation properties result in improved comfort level and saves heating and cooling costs. |

| 8. Sound Resistant Scientifically proven to provide better insulation to sound transmitted by air compared with other solid building materials. |

| 9. Water Resistant Starken AAC contains millions of closed microscopic cells which strongly resist moisture from passing through. |

| 10. Dimensional Accuracy Blocks and panels are manufactured under factory environment using state-of-the art modern machineries resulting in products with tighter dimensional tolerances. |

| 11. Good Workability Starken AAC can be easily sawn, cut, carved, nailed or drilled using ordinary hand tools. |

Comparison Between AAC and Brick