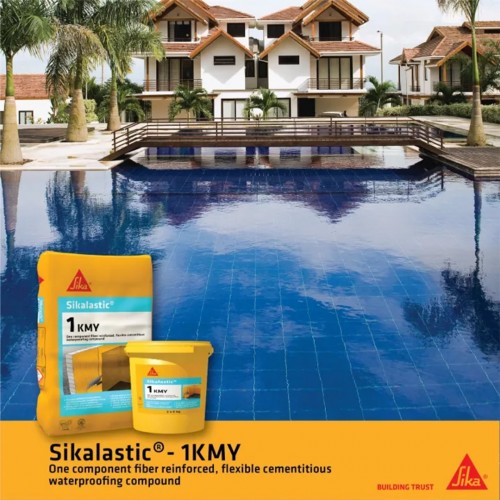

Sika Sikalastic 1KMY One Component Fiber Reinforced, Flexible Cementitious Waterproofing Compound 6KG x 2Pack (12KG)

Sika Sikalastic 1KMY One Component Fiber Reinforced, Flexible Cementitious Waterproofing Compound 6KG x 2Pack (12KG)

- Brand Sika

- Model: SK-LT1KMY-12

Description

• Sikalastic®-1 KMY is a one-component, flexible, fiber-reinforced mortar, based on cement modified with special alkali-resistant polymers.

• It also contains fine fillers, selected graded aggregates, plus special waterproofing additives to produce a flexible mortar that is ideal for waterproofing surfaces subject to flexural strain.

Characteristics/Advantages

• Easy to apply by brush, roller, or trowel.

• Can be applied to damp substrate.

• Good sag resistance and easy to apply on vertical surfaces.

• Flexible crack-bridging properties.

• Very good adhesion to most common substrates (concrete, cementitious mortar, stone, bricks, ceramic, and timber).

• Mixing ratio can be adjusted in order to obtain the consistency and workability.

Specification

Product Information

• Composition: Cement modified with polymers, selected aggregates, admixtures, additives and fibers.

• Packaging

- 20 kg bag

- 4 packs × 3 kg in box

• Shelf Life: 6 months from date of production

• Storage Conditions: Store properly in dry conditions, in undamaged and unopened, original sealed packaging. Protect from direct sunlight, rain and water. Not sensitive to frost.

• Appearance / Colour: Grey powder

• Density: Fresh mortar density: ~1.5 kg/l (at + 25 °C)

Technical Information

• Tensile Strength: 2.0 N/mm² (ASTM D412)

• Elongation at Break: > 23 % (ASTM D412)

• Crack Bridging Ability:

- > 0.50 mm (Class A 3, +23 °C) (EN 1062-7)

- ≥ 0.75 mm (+23 °C) (EN 14891 A.8.2)

• Tensile Adhesion Strength: On concrete, 28 days Dry substrate 1.3–1.5 N/mm² (ASTM D 7234-12, 20 mm Ø dolly)

Application Information

• Mixing Ratio:

- Application by roller ~0.35 L of water per 1 kg

- Application by brush ~0.3 L of water per 1 kg

- Application by trowel ~0.22 L of water per 1 kg

• Consumption:

- This depends on the substrate roughness; as a guide, ~1.0 kg/m²/mm

- Sikalastic®-1 KMY must be applied in minimum 2 coats

- Wet areas such as toilets, balconies: 2.0 kg/m²

- Critical areas such as swimming pools, ponds: 3.0 kg/m²

• Ambient Air Temperature: +5 °C min. / +40 °C max.

• Substrate Temperature: +5 °C min. / +40 °C max.

• Pot Life: ~30 minutes (at +23 °C)

• Waiting Time / Overcoating: Sikalastic®-1 KMY must be completely hardened before over-coating or water contact.

• Guide for waiting times at the following temperatures: +20 °C

- Horizontal coving by tiles ~2 days

- Vertical covering by tiles ~2 days

- Water emulsion coating ~2 days

- Immersion in water ~2 days

- Contact with drinkable water ~15 days

Times will vary due to ambient and substrate humidity.

Uses

• Waterproof protection of concrete structures including tanks, basins, pipes, swimming pools.

• Waterproofing external wall surfaces to be backfilled in the ground.

• Internal waterproofing of walls and floors, in basements, etc.

• Waterproofing of terraces and balconies over concrete or prepared existing tiles.

• General waterproofing of concrete surfaces.

• Compatible with SikaCeram® series, tilling system.

Application

Trowel

• Maintain an even pressure onto the substrate's surface to ensure a uniform distribution and thickness of Sikalastic®-1 KMY. Trowel in two directions (at right angles). Maximum recommended thickness is 2 mm per coat. The final thickness when applied by trowel will depend on the method of application and level or grade of exposure / waterproofing required. The highest waterproofing performance is obtained by applying Sikalastic®-1 KMY using a trowel in at least 2 coats, to a total thickness of 3–4 mm. *Spray application is applicable with the correct equipment. Please consult Sika’s representative for more information.

Brush or Roller

• Application by brush or roller must be undertaken with maximum attention to completely cover the substrate's surface uniformly. Brush or roll in two directions (at right angles). The maximum recommended thickness for these method of application is 1 mm per coat. In these situation, the application of min. 2–3 coats is required.

Joints / Critical areas

• At floor joints and other critical areas (for example, any junctions with vertical surfaces), the watertightness can be reinforced by using Sika® SealTape-F. Sika® SealTape-F must be fixed directly onto the first coat of Sikalastic®-1 KMY whilst it is still wet, and then covered by a second coat of Sikalastic®-1 KMY.

Curing Treatment

• Generally not required but precautions should be taken for applications done directly under sunlight and windy condition.

Important Considerations

IMPORTANT CONSIDERATIONS

▪ Avoid application under direct sun light, rain and/or strong wind. Setting time can be influenced by high relative humidity, particularly in closed rooms or basement. Adequate ventilation is recommended when applying Sikalastic®-1 KMY.

• Protect from rain for at least 24–48 h after application.

▪ If a solvent based paint must be painted on Sikalastic®-1 KMY, carry out preliminary testing in order to ensure the solvents do no damage the waterproofing layer.

Approvals / Standards

• SPAN Approval: SPAN/PPI/1683-2016 (Potable Water)

• SINGAPORE GREEN LABEL: 032-118-3205 "Environmentally Preferred Coating"