Sika Sikabond 124 Instant Nails Multipurpose Adhesive 333G

Sika Sikabond 124 Instant Nails Multipurpose Adhesive 333G

- Brand Sika

- Model: SK-SB124

Description

• SikaBond®-124 Instant Nails is a 1-part, rigid, adhesive with high final strength that bonds the most common construction & industry material substrate.

• Internal and covered external use.

Characteristics / Advantages

• Easy to apply.

• Rapid initial grab after flash off.

• Rapid strength gain.

• Wide adhesion range.

Specification

Product Information

• Composition: Synthetic rubber

• Packaging: 333 g cartridge, 12 cartridges per box

• Colour: Wood Brown

• Shelf Life: 18 months from the date of production

• Storage Conditions: The product must be stored in original, unopened and undamaged sealed packaging in dry conditions at temperatures between +5 °C and +30 °C. Always refer to packaging.

• Density: ~1.20 kg/l (ASTM D1002)

Technical Information

• Shore A Hardness: ~80 (after 28 d) (ISO 868)

• Shear Strength: ~3.5 N/mm² (0.1 mm adhesive thickness) (ASTM D1002)

• Service Temperature: −30 °C min. / +60 °C max. (maximum 5 freeze / thaw cycles)

Application Information

• Yield:

- 1 Cartridge (333 g)

~11 m bead

~100 spots

Dimension

Nozzle diameter = 6 mm

~30 g per linear meter

Diameter = 30 mm

Thickness = 4 mm

• Ambient Air Temperature: +5 °C min. / +40 °C max.

• Substrate Temperature: +5 °C min. / +40 °C max., min. 3 °C above dew point temperature

• Open Time: ~1–5 min (23 °C / 50 % r.h.)

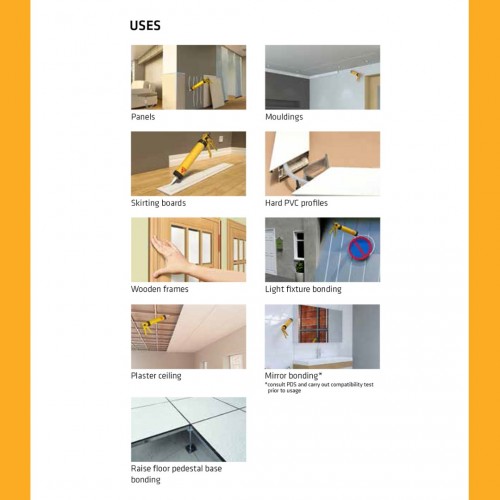

Uses

An adhesive to bond most components, such as:

• Skirting boards

• Wooden frames

• Battens

• Panels

• Mouldings

• Hard PVC profiles

• Sheet boards

• Metal protection angles

Application Method / Tools

One Way Method

• This method is recommended for heavier panels or where load or stress is expected. Apply a 4 to 6 mm bead of SikaBond®-124 Instant Nails using a cartridge gun, making sure the beads are no more than 50 mm apart. Bring both substrates immediately together and clamp, nail or screw for a minimum of 24 hours. For butt joints use adhesive on both panel edges.

Two Way Method

• Apply adhesive as in one way method, bring together substrates, and press firmly over entire surface to transfer adhesive. Then pull apart. Allow adhesive to dry off up to 3 minutes (depending on ambient conditions) reposition the objects and press together with a hammer and a padded block to ensure maximum contact. Maximum bond strength will be achieved in 12 to 72 hours, depending on substrates and environmental conditions. Heavy panels may require temporary mechanical fastening until maximum strength is achieved.

Important Considerations

▪ For good workability, the adhesive temperature should be +20 °C.

▪ Application during high temperature changes is not recommended (movement during curing).

▪ Before bonding, check adhesion and resistance of paints and coatings by carrying out a trial.

Sensitive application:

SikaBond®-124 Instant Nails contains solvents that might degrade and affect sensitive components and substrates (e.g. plastics). Before using on any of the below substrates, ensure compatibility by carrying out preliminary trials. Or contact Sika Technical Services:

▪ Overpainting

▪ Mirrors

▪ Natural Stone

▪ Plastics, such as, polyethylene (PE), polypropylene (PP), polytetrafluoroethylene (PTFE/ Teflon) and certain plasticised synthetic materials.

▪ Colour variations may occur due to exposure to chemicals, high temperatures and/or UV-radiation. Discolouration does not adversely affect the technical performance or durability of the product.

▪ Always use SikaBond®-124 Instant Nails in conjuction with mechanical fixings for overhead applications or heavy components.

▪ For very heavy components, provide temporary support until SikaBond®-124 Instant Nails has fully cured.

▪ Single Bond Method: Full surface applications / fixings are not recommended since the inner part of the adhesive layer may never cure.

▪ High levels of humidity or exposure to water can lead to adhesion failure.

▪ Excessive movement can lead to adhesion failure.

Limitations:

▪ Do not use on bituminous substrates, natural rubber, EPDM rubber or on any building materials which might leach oils, plasticisers or solvents that could degrade the adhesive.

▪ Do not use for bonding glass if the bond line is exposed to sunlight.

▪ Do not use for structural bonding.

Disclaimer

All product images shown are for illustration purposes only. Actual products may vary in terms of size, type, brand, version, color, and other relevant characteristics.