STAHLCON® HE 0.55/35 Steel Fibre Hooked-End For Concrete Reinforcement 0.55MM (D) x 35MM (L) - 20KG/BAG

STAHLCON® HE 0.55/35 Steel Fibre Hooked-End For Concrete Reinforcement 0.55MM (D) x 35MM (L) - 20KG/BAG

RM204.00

Price in reward points: 81600

- Model: STAHLCON HE 0.55/35

Products Sold: 0

Product Views: 65

Description

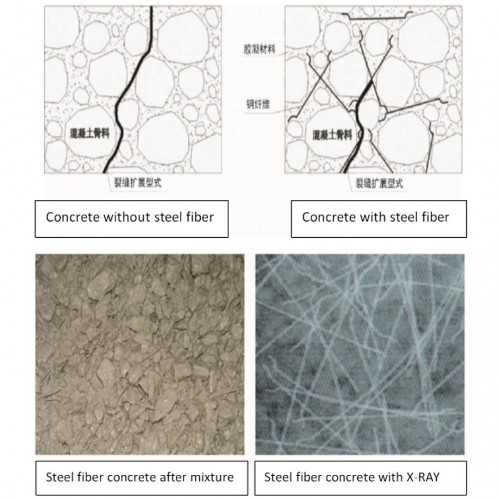

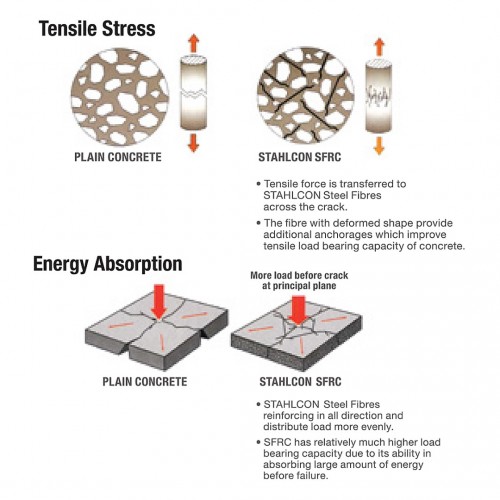

STAHLCON® HE 0.55/35 is a high-strength steel fibre designed to improve the mechanical properties of concrete. With its hooked-end design, it enhances bonding, crack resistance, and durability, making it suitable for various structural and industrial applications. It provides an efficient alternative to conventional reinforcement methods like rebar and wire mesh.

Specification

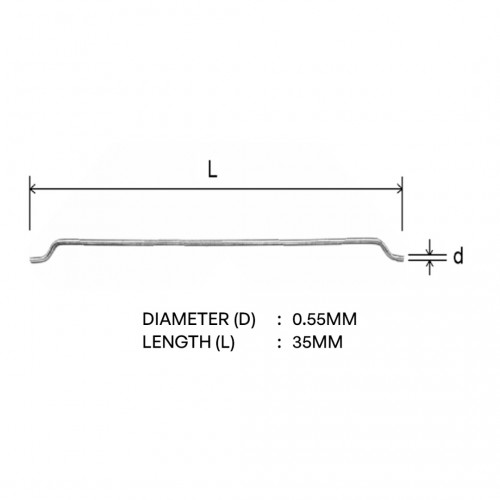

- Diameter: 0.55mm

- Length: 35mm

- Aspect Ratio: 63

- Quantity (pc/kg): ± 14,490 fibre/kg

- Tensile strength, Rm 1200 MPa

- Elastic modulus, E 205,000 MPa

- Fibre type BS EN14889-1:2006, Group I – cold-drawn wire

- Wire (raw material) Conforms to BS EN10016-2 and JIS3505

- Material: High-strength steel

- Packaging: 20kg per bag

- Compliance: Meets international standards for concrete reinforcement

Material

- Manufactured from high-tensile strength steel

- Hooked-end fibres for enhanced anchorage and load distribution

- Corrosion-resistant properties for long-term durability

Features

- Improves tensile and flexural strength of concrete

- Enhances crack resistance and impact durability

- Provides better stress distribution compared to traditional reinforcement

- Reduces plastic shrinkage and settlement cracks

- Increases fatigue resistance and load-bearing capacity

Uses

- Industrial flooring and warehouse slabs

- Pavements, roads, and bridge decks

- Precast concrete elements

- Tunnel linings and shotcrete applications

- Foundations and structural concrete applications

Application

- Shotcrete applications – segmental lining tunnel

- Slope stabilization

- Rehabilitation of old structures

- Swimming pool

- Overlays

- Precast products

- Segmental lining

- Cellar walls

- Blast-proof structures

- Safety vaults etc.

Approvals

- Conforms to BS EN 14889-1:2006

- Conforms to ASTM A820

- Conforms to MS 2338-2010