Obaproof TO-1000 Torch Applied Bituminous Waterproofing Membrane 3.0MM (T) x 1M (W) x 10M (L) x 40KG - Mineral/Sand

Obaproof TO-1000 Torch Applied Bituminous Waterproofing Membrane 3.0MM (T) x 1M (W) x 10M (L) x 40KG - Mineral/Sand

- Brand Obaproof

- Model: OBP-TO1000

Available Options

Description

Obaproof TO-1000 is a high strength pre-fabricated torch on the type waterproofing membrane. There are 2 types: mineral and sand finishing surface. For mineral, the type can be applied for exposing and trafficable, suitable for re-waterproofing and new RC concrete as well. For sand type, usually need to apply a protective screed, suitable to apply on a new RC surface.

Uses

- Used as a waterproofing membrane on flat or pitched roofs (as an exposed or concealed system), foundations and basements, terraces and balconies, cut and cover tunnels, subways.

- Can be applied in a single layer or in multi-layer applications

Characteristic & Advantages

- Excellent stability when exposed to stresses such as movement and temperature extremes

- Reinforced polyester allows the sheet to be flexible, durable and resistant to heat, aging, and puncture

- Uniform thickness of 3/4mm

- Easily installed using flame torch methods

- Good chemical resistance

- Water and vapor proof

Advantage

- Standard thickness

- Exposable to UV

- Trafficable

- High tensile strength

- Puncture resistant

- Good bonding

- Best for maintenance work

Application area

- Kitchen area

- RC flat roof

- Balcony

- Car porch roof

- Driveway

- RC gutter

- Planter box

- Toilet / Bathroom

Specifications

- Appearance: Sand or Mineral finishing (The color of mineral finishing could be different from batch to batch.)

- Thickness (Sand type): 3.0mm

- Thickness (Mineral type): 3.0mm

- Dimension: 1m x 10m

- Weight (Sand type): 4kgs/m2

- Weight (Mineral type): 4kgs/m2

- Crack bridging: >2mm

- Tensile strength: > 5.4 Mpa

- Elongation at break: 63%

A thin layer of the primer by bitumen coating is required

Application Tools

- Torch gun

- Roller (For Primer)

Dosage

- Minimum at 1 Layer.

- Overlap: 75mm.

- Vertical height: 300mm upturn and above

Packaging

- 3.0MM (T) x 1M (W) x 10M (L) x 40KG roll

Material Selection

- There are two types of Obaproof TO-1000 torch on the membrane; mineral surface usually for expose system and the sand surface need a cement screed.

Site Visit

Prior to waterproofing installation arrange a visit to the project site to inspect and certify that concrete surfaces are in acceptable condition to receive waterproofing treatment.

Remove The Existing Waterproofing Membrane

For repairing work, If there is any existing waterproofing system such as torch on membrane, acrylic coating, PU coating on top of screed, the removal work is necessary.

Verify The Substrates

Verify that concrete or screed surfaces are sound and clean, and that form release agents and materials used to cure the concrete are compatible with waterproofing treatment.

Examination & Repair For Defects

Examine defects such as honeycomb, water ponding point, and cracks. Such defects to be repaired by cement grout, patching mortar, or epoxy grout.

Surface Preparation

Clean the dusty surfaced, remove cement ash and trashed, ensure the surface is good to received waterproofing.

Angle Fillet

Form the angle fillet between vertical and horizon area such as the area between the parapet wall and floor slab. The angle fillet can be done by normal cement grout mix with water and sand. The angle fillet required minimum 25mm x 25mm, or 50mm x 50mm will be better.

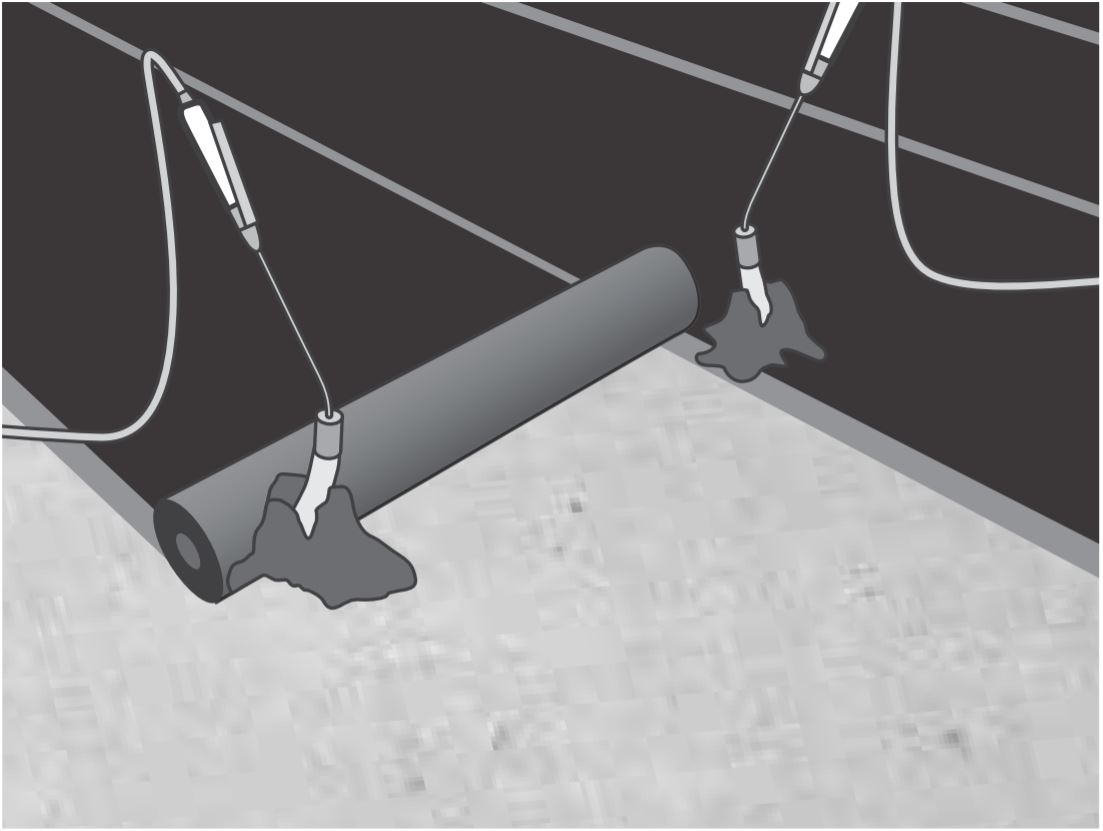

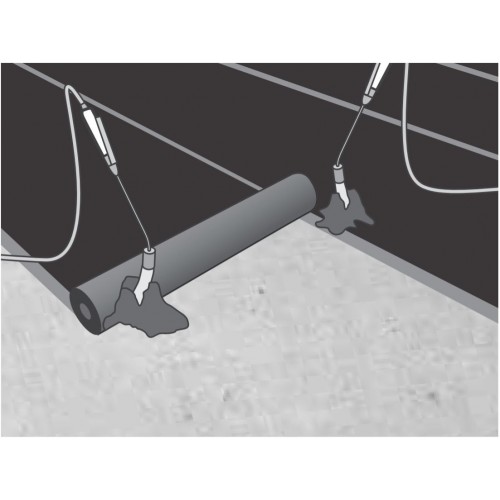

Application Of Torch-On Membrane

After the primer coat, can apply the Obaproof TO-1000 4mm torch on membrane, lay the Obaproof TO-1000 on gutter/scupper drain first, followed by the floor (start from low to high gradient) and lastly, the skirting. Use torch gun to torch the Obaproof TO-1000 equally to make sure all surfaces been torch and stick on the floor especially the overlapping area, must be fully torched to create the best bonding on the joint.

Primer

Apply a thin layer of the bitumen primer coat. The dosage of primer at 0.25kg/m2.

Ponding Test

24 to 48 hours of water ponding test (depend on consultant approval and site condition) are to be carried after the waterproofing membrane application has been done. During the ponding test, check the soffit on the 2nd day to ensure there is no watermark or leaking.

Curing Time

Bitumen primer curing time at 4-8hours depends on weather condition

Protection

During curing time, water ponding test, the prevention of human traffic into that area is required.

Cleaning

Any of bitumen primer can be clean by clean water or thinner.

Safety

Prevent bitumen primer get contact with the eye. During the torch on work, suggest to fully cover by non-flammable material and work

carefully especially during the heavy wind.

Disclaimer

All product images shown are for illustration purposes only. Actual products may vary in terms of size, type, brand, version, color, and other relevant characteristics.